Like our best friend in the whole world says "Keep it as simple as possible...but no simpler."

I think version 1.0 (http://www.bimmerfest.com/forums/showthread.php?t=774371) does an ok job: after disassembling it I noticed there was still a certain amount of oil passing through.

I did some more researching and found that coalscer filter works in 2 steps: step 1 they saturate by coalescing (http://www.merriam-webster.com/dictionary/coalesce) droplets of oil in the blow-by; once they get to a certain saturation they start with step 2 which is basically shedding the oil (you can read some more here: http://www.parker.com/literature/Racor/7678 (CCV Technical Brochure).pdf). If oil is not shed then is picked back up by the gasses... Well, I suspect my trick is not doing a good job at shedding the oil: it's basically too simple.

Well... FINALLY I found a place to put the Mann+Humme ProVent 200 in our tight engine bay. Here's a teaser:

![Image]()

Stay tuned for some cool stuff:

1) Reroute the line going from the vacuum pump to the brake booster

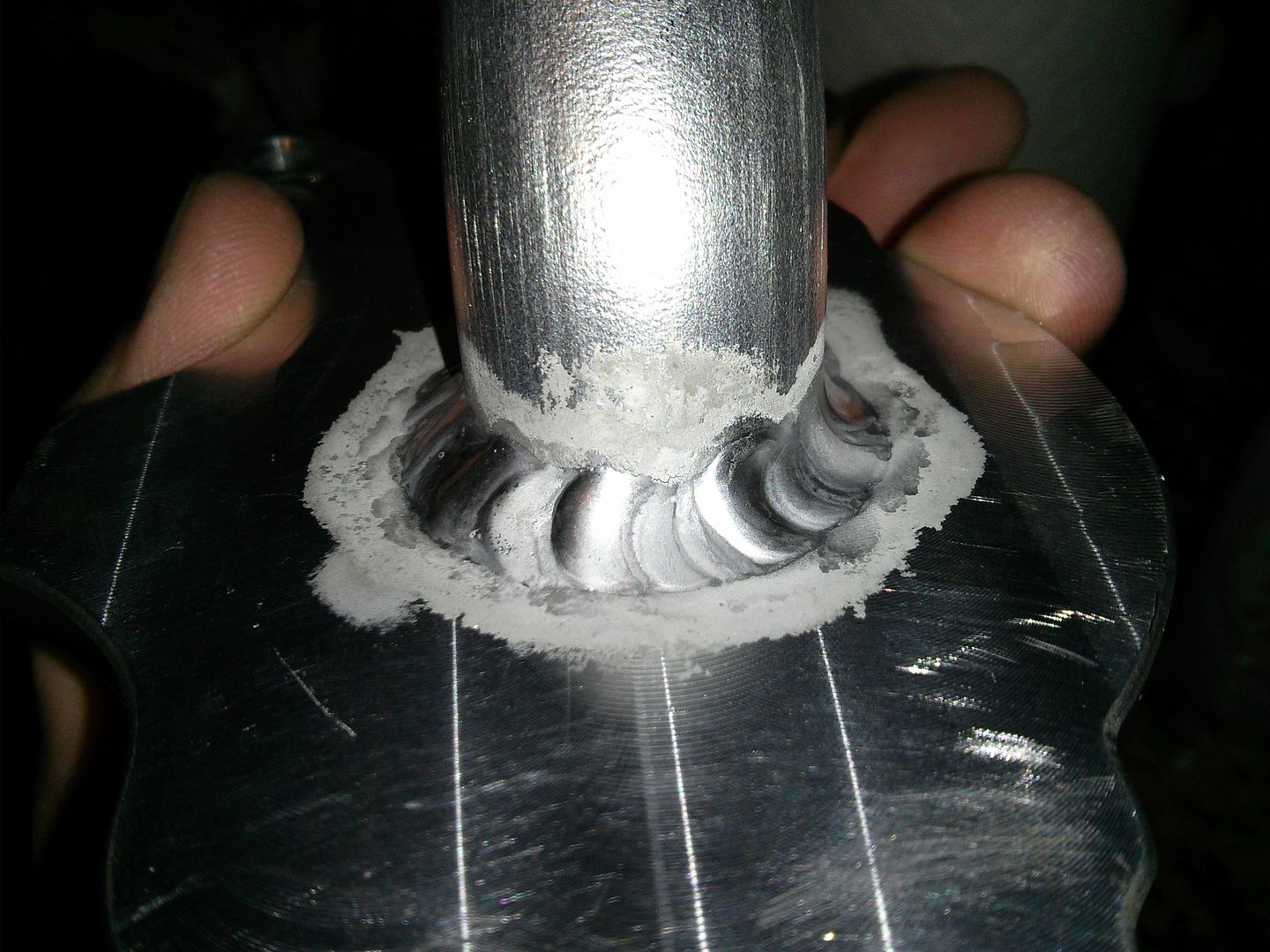

2) A "take off plate" that will replace the stock CCV and will allow me to route the blow-by to the Provent and back from the back of the engine

3) After proper testing, I'm planning on modifying the dipstick tube to use it as oil return line

I think version 1.0 (http://www.bimmerfest.com/forums/showthread.php?t=774371) does an ok job: after disassembling it I noticed there was still a certain amount of oil passing through.

I did some more researching and found that coalscer filter works in 2 steps: step 1 they saturate by coalescing (http://www.merriam-webster.com/dictionary/coalesce) droplets of oil in the blow-by; once they get to a certain saturation they start with step 2 which is basically shedding the oil (you can read some more here: http://www.parker.com/literature/Racor/7678 (CCV Technical Brochure).pdf). If oil is not shed then is picked back up by the gasses... Well, I suspect my trick is not doing a good job at shedding the oil: it's basically too simple.

Well... FINALLY I found a place to put the Mann+Humme ProVent 200 in our tight engine bay. Here's a teaser:

Stay tuned for some cool stuff:

1) Reroute the line going from the vacuum pump to the brake booster

2) A "take off plate" that will replace the stock CCV and will allow me to route the blow-by to the Provent and back from the back of the engine

3) After proper testing, I'm planning on modifying the dipstick tube to use it as oil return line