If you are planning to remove your valve cover one day (for VCG or VANOS seals), you might want to read this just in case.

The following day after I was done with my VANOS seals kit installation, the SES light illuminated and the OBD 2 scanner informed me of 2 codes: P0491 and P0492. Great! The VANOS codes (P0014 and P0015) are gone and the secondary air control system codes are now registered. I'll explain later why it's not a coincidence. But at first I did not suspect it was related to my VANOS job. I went online and started reading on what the secondary air control system consists of. Air pump (not shown here), check valve (#1), solenoid vacuum control switch (#5), another little non-return valve (#6) and lots of vacuum line (#3,4,7) to connect these components as well as relays and fuses (not shown here).

![Image]()

Nice! How do I know which component is bad and causes the codes? Searched and found this very helpful document that describes the diagnostic procedures for every unit of the E46 secondary air control system. See pages 6 and 7 of this newsletter pdf:

https://www.bavauto.com/newsletter/2008_n408_newsletter.pdf

What follows is the abbreviated version of the diagnostic procedure that pertained to my specific case. Refer to the above-mentioned link for the complete protocol.

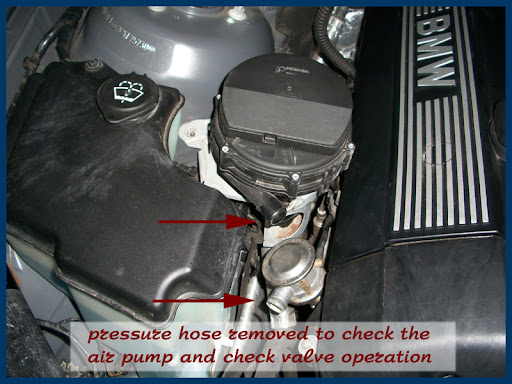

Step # 1: rule out the pump. Easy, mine works like a beast. Step # 2: rule out the check valve. Well, it does not seem to open...

![Image]()

Need to do the vacuum test. After a short trip to AutoZone I'm a happy owner of a MityVac hand vacuum pump. Now we'll see if the valve works or not. After an hour of trying to apply vacuum to the check valve, I realized that the MityVac vacuum pump the good people at AutoZone had sold me was defective: the vacuum release nipple was jammed. After fixing the vacuum pump I successfully applied vacuum to the valve, started the car and the valve opened, after releasing the vacuum it closed. So, the valve works just fine.

![Image]()

It's good news and bad news at the same time. The good news is that the 2 most expensive components are ruled out as perfectly working and the rest of the units are relatively cheap. The bad news is the fact that the rest of the components are located somewhere behind and under the manifold and I do not have a clear idea of how to reach them. So, to start with I decided to check the vacuum line going from the check valve to the solenoid vacuum control switch. The line runs around the valve cover and behind the manifold. You need to remove the cabin filter assembly and valve cover and fuel rail trim covers. And lo and behold! The vacuum line is disconnected at the little adapter that connects 2 hoses together, not even torn but just disconnected.

![Image]()

What happened is upon the reinstallation of the valve cover after the VANOS job I was moving the bundles of O2 sensor wires out of the way and inadvertently tugged at the hose disconnecting it. Did not even notice it at that time.

![Image]()

So that was an easy fix, the codes are gone. The moral of the story? Be careful with that vacuum hose back there when you remove and reinstall the valve cover. The hose also becomes brittle and brakes at the check valve but it's much easier to notice it there. So, although this all could have been avoided had I been more careful, it was a good experience and a chance to read up on how the secondary air control system works and it's diagnostic procedures.

The following day after I was done with my VANOS seals kit installation, the SES light illuminated and the OBD 2 scanner informed me of 2 codes: P0491 and P0492. Great! The VANOS codes (P0014 and P0015) are gone and the secondary air control system codes are now registered. I'll explain later why it's not a coincidence. But at first I did not suspect it was related to my VANOS job. I went online and started reading on what the secondary air control system consists of. Air pump (not shown here), check valve (#1), solenoid vacuum control switch (#5), another little non-return valve (#6) and lots of vacuum line (#3,4,7) to connect these components as well as relays and fuses (not shown here).

Nice! How do I know which component is bad and causes the codes? Searched and found this very helpful document that describes the diagnostic procedures for every unit of the E46 secondary air control system. See pages 6 and 7 of this newsletter pdf:

https://www.bavauto.com/newsletter/2008_n408_newsletter.pdf

What follows is the abbreviated version of the diagnostic procedure that pertained to my specific case. Refer to the above-mentioned link for the complete protocol.

Step # 1: rule out the pump. Easy, mine works like a beast. Step # 2: rule out the check valve. Well, it does not seem to open...

Need to do the vacuum test. After a short trip to AutoZone I'm a happy owner of a MityVac hand vacuum pump. Now we'll see if the valve works or not. After an hour of trying to apply vacuum to the check valve, I realized that the MityVac vacuum pump the good people at AutoZone had sold me was defective: the vacuum release nipple was jammed. After fixing the vacuum pump I successfully applied vacuum to the valve, started the car and the valve opened, after releasing the vacuum it closed. So, the valve works just fine.

It's good news and bad news at the same time. The good news is that the 2 most expensive components are ruled out as perfectly working and the rest of the units are relatively cheap. The bad news is the fact that the rest of the components are located somewhere behind and under the manifold and I do not have a clear idea of how to reach them. So, to start with I decided to check the vacuum line going from the check valve to the solenoid vacuum control switch. The line runs around the valve cover and behind the manifold. You need to remove the cabin filter assembly and valve cover and fuel rail trim covers. And lo and behold! The vacuum line is disconnected at the little adapter that connects 2 hoses together, not even torn but just disconnected.

What happened is upon the reinstallation of the valve cover after the VANOS job I was moving the bundles of O2 sensor wires out of the way and inadvertently tugged at the hose disconnecting it. Did not even notice it at that time.

So that was an easy fix, the codes are gone. The moral of the story? Be careful with that vacuum hose back there when you remove and reinstall the valve cover. The hose also becomes brittle and brakes at the check valve but it's much easier to notice it there. So, although this all could have been avoided had I been more careful, it was a good experience and a chance to read up on how the secondary air control system works and it's diagnostic procedures.