Part is on order & hopefully a review for the Bimmerfest Community will soon follow.

Stated Purpose:

The BMW N62 V8 secondary air injection system can become blocked, not allowing air flow from the secondary air pump to reach the exhaust system. Therefore, the O2 sensors before the catalytic converters don***8217;t register a dip in mixture and it sets a code and results in the check engine light to come on.

Using the AGA Secondary Air Injection Cleaner Tool Kit takes an extremely expensive repair down to a fraction of the cost!

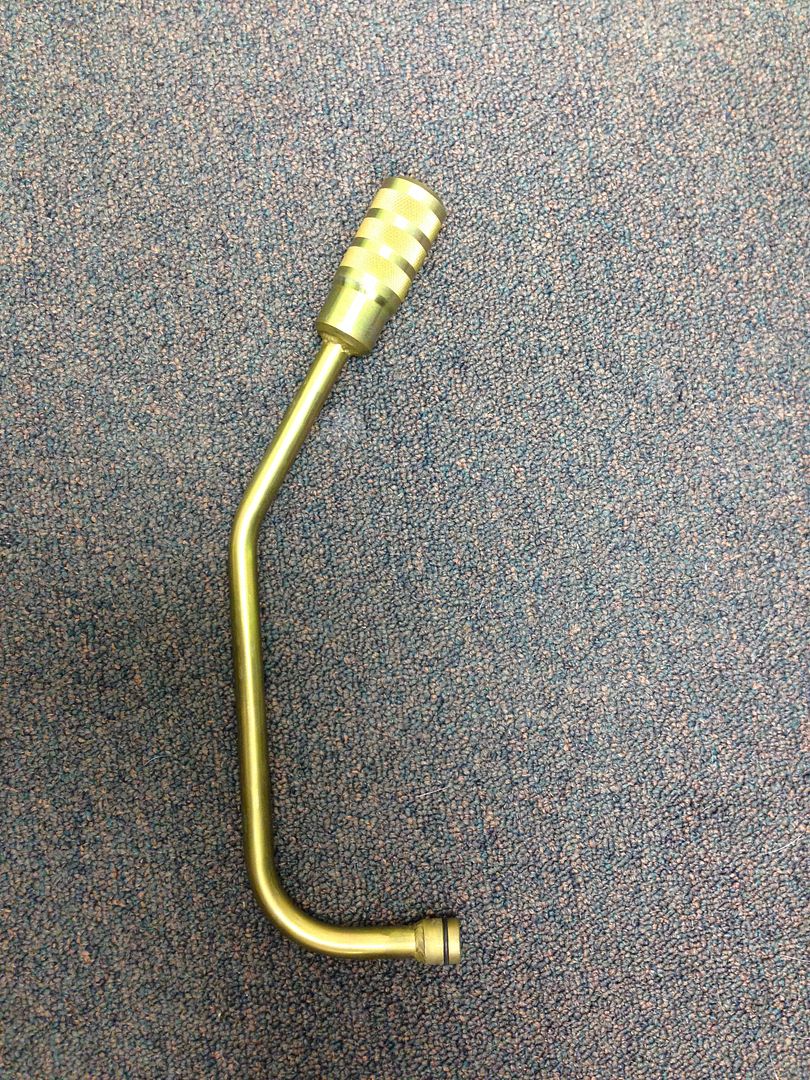

Air comes in from the secondary air injection pump, through a hose and into the hard line where it splits off. The air comes into the emissions control valve (which is a one way valve), passes through an aluminum tube and into the cylinder head. This is where the restriction is that needs to be cleaned out.

With the AGA Secondary Air Injection Cleaner Tool Kit, the repair can be done with the cylinder heads and engine in the vehicle!

More info soon.

Stated Purpose:

The BMW N62 V8 secondary air injection system can become blocked, not allowing air flow from the secondary air pump to reach the exhaust system. Therefore, the O2 sensors before the catalytic converters don***8217;t register a dip in mixture and it sets a code and results in the check engine light to come on.

Using the AGA Secondary Air Injection Cleaner Tool Kit takes an extremely expensive repair down to a fraction of the cost!

Air comes in from the secondary air injection pump, through a hose and into the hard line where it splits off. The air comes into the emissions control valve (which is a one way valve), passes through an aluminum tube and into the cylinder head. This is where the restriction is that needs to be cleaned out.

With the AGA Secondary Air Injection Cleaner Tool Kit, the repair can be done with the cylinder heads and engine in the vehicle!

More info soon.